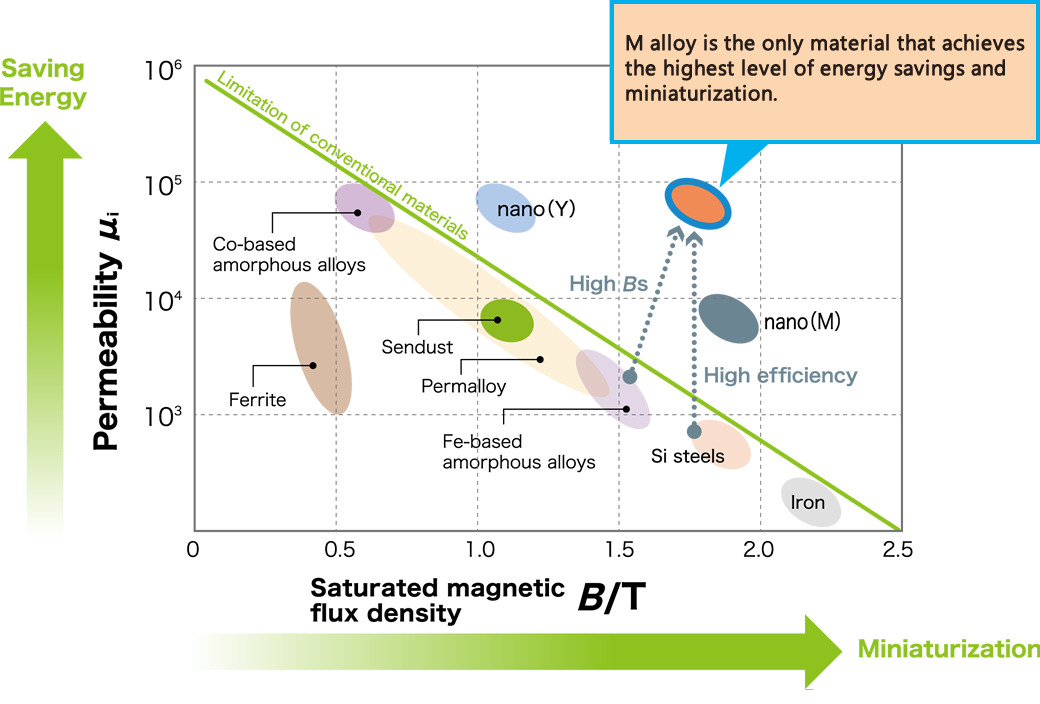

Features of M alloy

The only innovative soft magnetic material that combines the highest magnetic flux density with the best soft magnetic properties.

Nanocrystalline soft magnetic alloy “M alloy” has high magnetic flux density, excellent soft magnetic properties, and low loss, which were considered difficult to achieve in the past.

We have established new alloy compositions and nanocrystallization heat treatment technologies for application to small electronic components, motors, and transformers, and are engaged in product and technology development.

| magnetic flux density | (B)~1.7T |

|---|---|

| coercive force | (Hc)~0.6-2A/m |

| permeability | (μ@1kHz)>40000 |

| Plate thickness | 14~25μm (Tolerance within 2μm) |

| Plate width | 20~210mm |

| cost | Almost equal to Fe-based amorphous alloys and high-grade silicon steel, less than half of conventional nanocrystalline material (Y) |

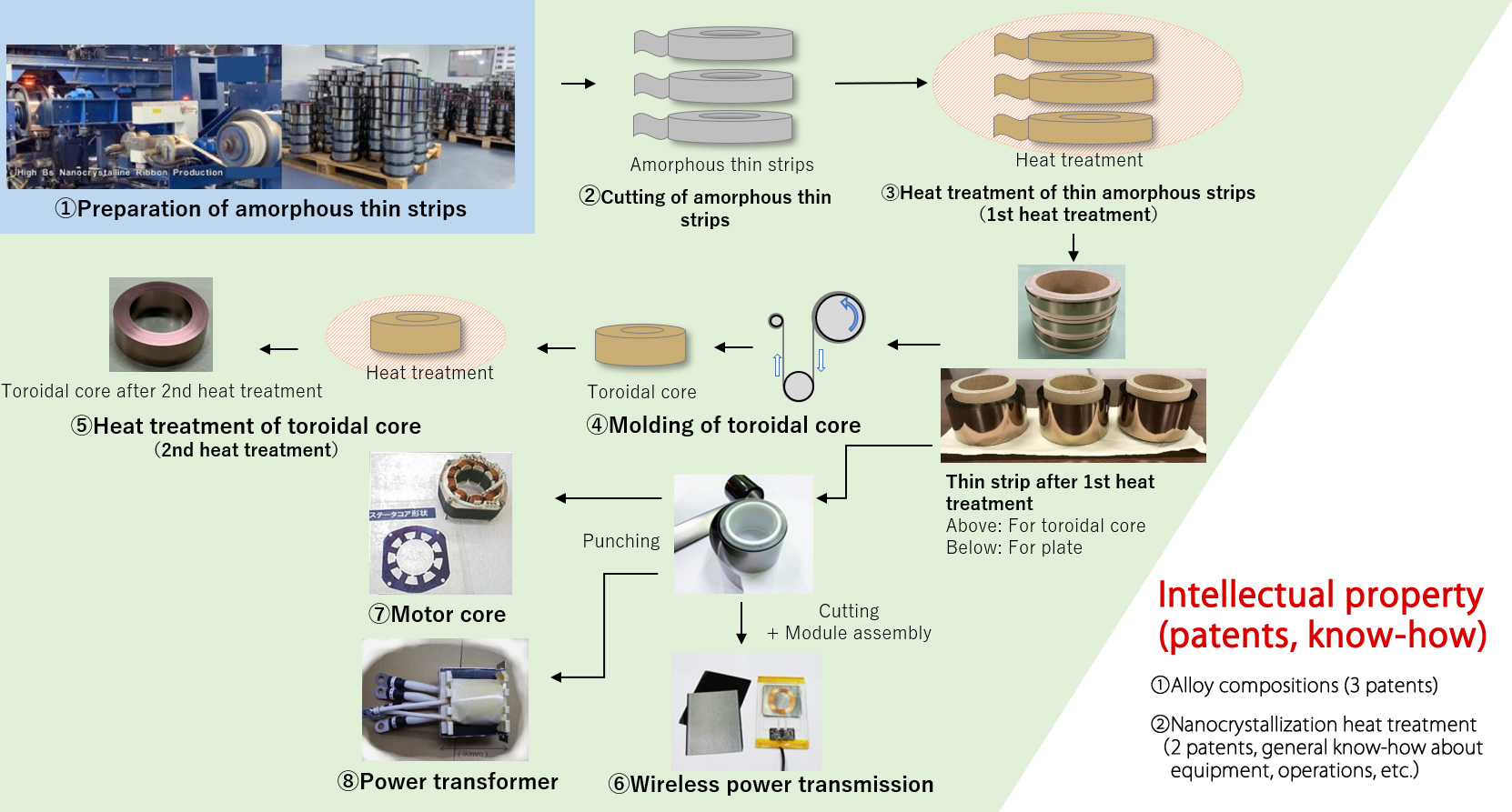

Our Technology

1 Nanocrystallization heat treatment of M alloy (mass production) and process to commercialization

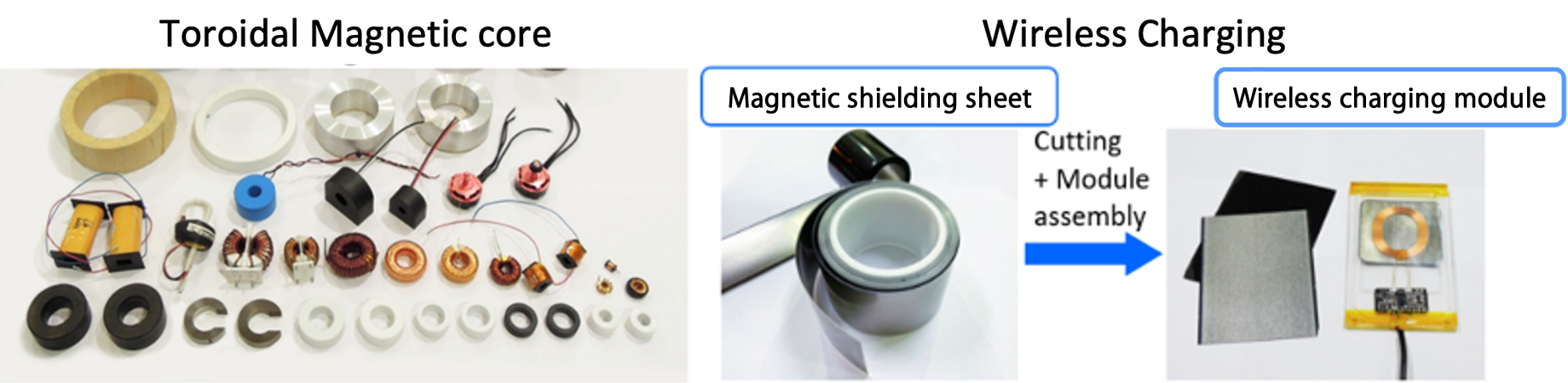

2 Application to magnetic (electronic) components (amorphous, compared to conventional nanocrystals)

3 Current magnetic properties (amorphous, compared to conventional nanocrystals)

high B, further improvement of soft magnetic properties underway

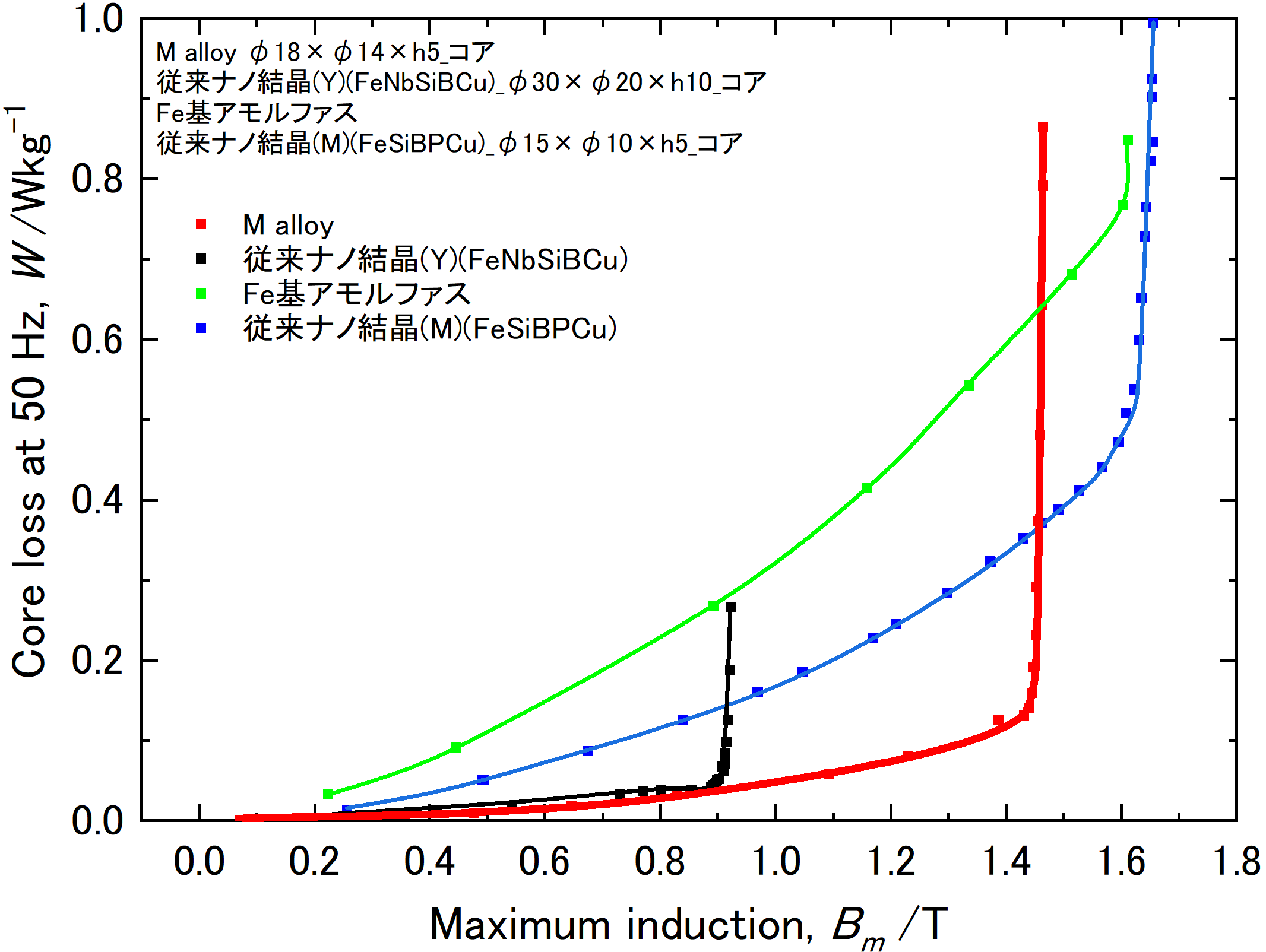

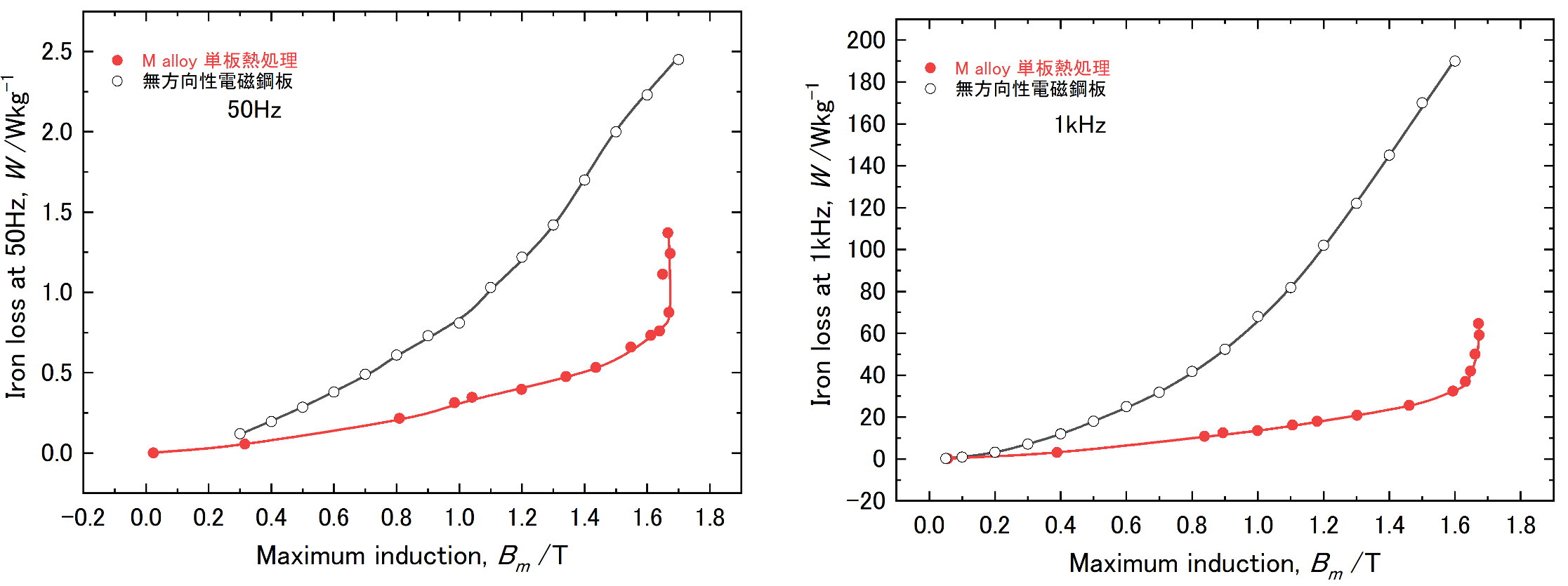

Dependence of iron loss on magnetic flux density

Comparison of iron loss (W/kg) at 50 Hz

| Toroidal core | Bm(T) | ||

|---|---|---|---|

| 0.8 | 1.0 | 1.2 | |

| M alloy core | 0.03 | 0.05 | 0.07 |

| Conventional nanocrystals(Y)(FeNbSiBCu) | 0.03 | Unmeasurable | |

| Fe-based amorphous | 0.23 | 0.35 | 0.44 |

| Conventional nanocrystals(M)(FeSiBPCu) | 0.11 | 0.17 | 0.24 |

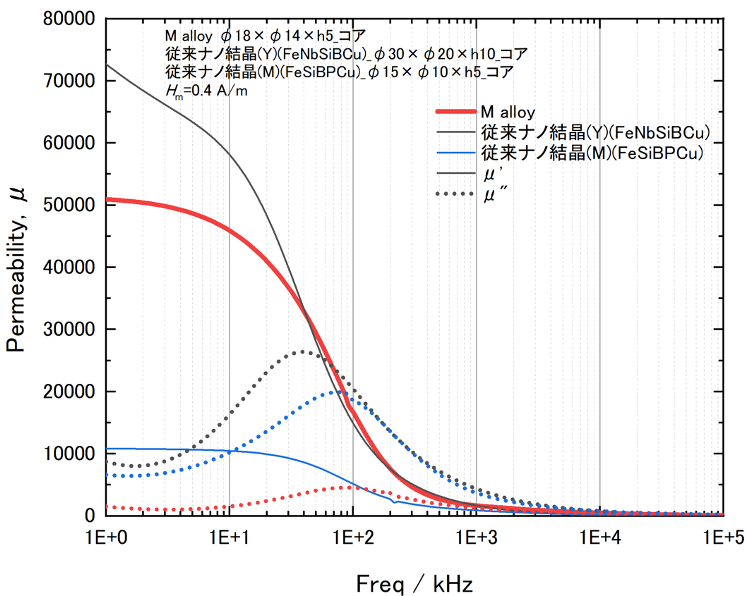

Frequency dependence of magnetic permeability

Frequency dependence of magnetic permeability (µ´)

| Toroidal core | Frequency(kHz) | |||

|---|---|---|---|---|

| 1 | 10 | 100 | 1,000 | |

| M alloy core | 51,000 | 46,000 | 17,000 | 1,650 |

| Conventional nanocrystals(Y)(FeNbSiBCu) | 72,000 | 58,000 | 15,000 | 1,650 |

| Conventional nanocrystals(M)(FeSiBPCu) | 10,000 | 9,600 | 4,800 | 740 |

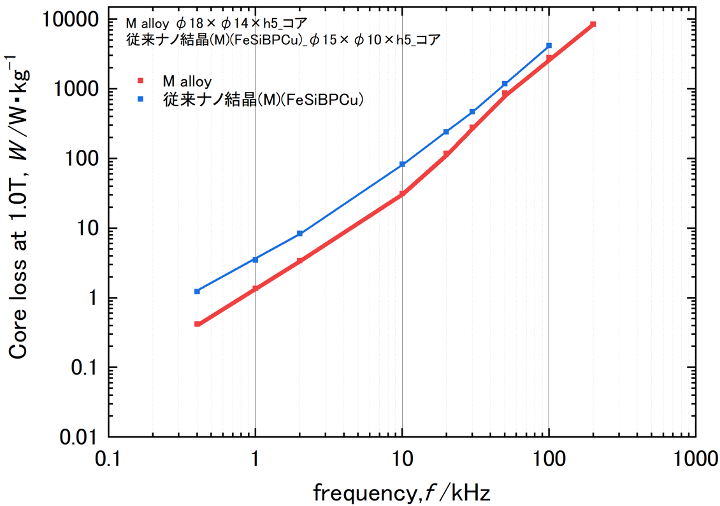

Frequency dependence of iron loss at 1.0T

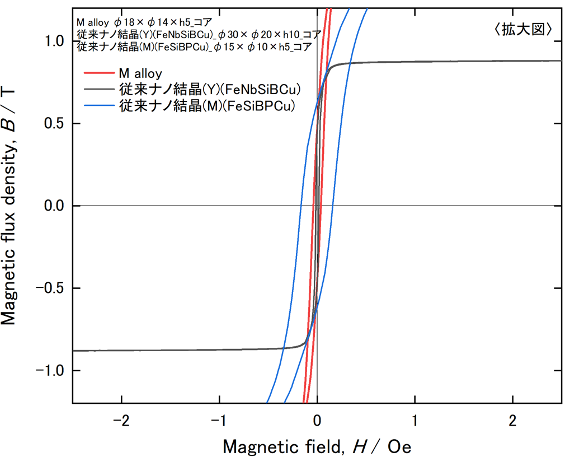

Coercivity in DC BH-loop

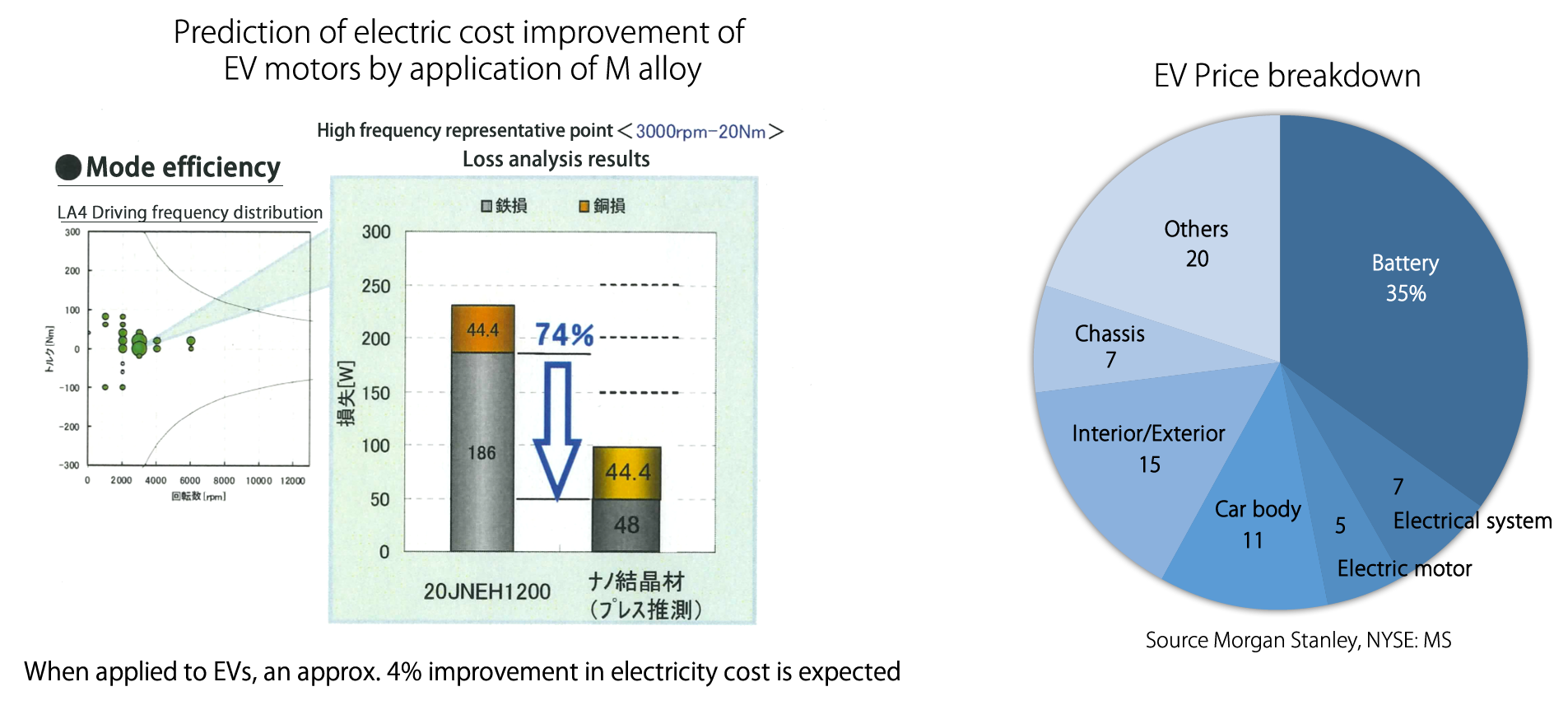

4 Application to motors and transformers

The application of M alloy to EV motors is expected to significantly improve power consumption, reduce the load on batteries, and improve driving range. In addition, the price of batteries, which account for 35% of the total price of EVs, can be lowered. This in turn is expected to reduce the price of EVs, which has been a barrier to the spread of EVs.

Comparison of iron loss dependence on magnetic flux density

| Single plate | Iron loss(W/kg) | |||||

|---|---|---|---|---|---|---|

| W1.0T/50Hz | W1.5T/50Hz | W1.0T/1kHz | W1.5T/1kHz | W1.0T/10kHz | W1.5T/10kHz | |

| M alloy core | 0.32 | 0.60 | 14.1 | 27.0 | 215 | 540 |

| Non-directional electromagnetic steel plate | 0.81 | 2.0 | 68.0 | 170 | Unmeasurable | Unmeasurable |

Contact Us

LABO・CITY SENDAI

6-6-3 Minamiyoshinari, Aoba-ku, Sendai

Miyagi, 989-3204 JAPAN

TEL:+81-22-343-6877

E-mail:info akmakino.com

akmakino.com