Latest News

Message from the Representative Director

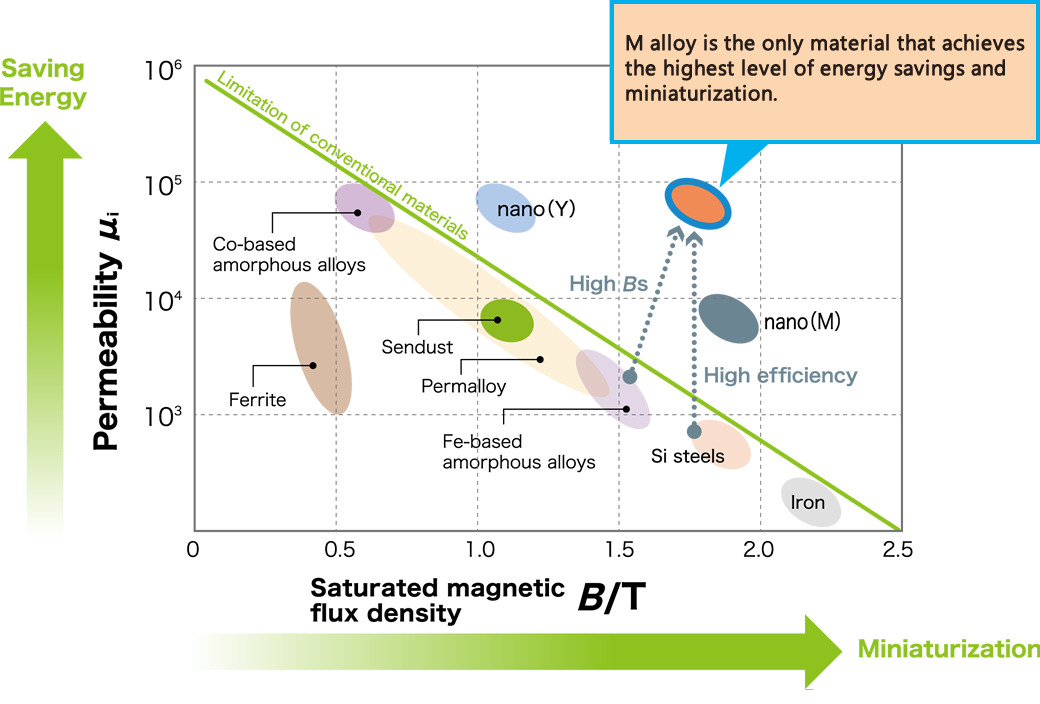

In 2009, while I was working at Tohoku University, we developed a new Fe-based nanocrystalline material (FeSiBPCu) that combines high magnetic flux density and excellent soft magnetic properties, which have long been sought after in the field of soft magnetic materials, and which have traditionally been considered extremely difficult to achieve. We succeeded in developing it ahead of the rest of the world. Furthermore, we have demonstrated that by using this material as a core material, it is possible to significantly improve efficiency, save energy, and downsize motors, transformers, and magnetic components.

The key issues for the evolution from the university research level to social implementation are the stable production and supply of materials at low cost and the realization of magnetic properties that are better than those at the laboratory level in components of various shapes and sizes. More than 10 years have passed since its the invention of M alloy, and even in a variety of components (wound cores, plates), using inexpensive raw materials, the soft magnetic properties are stable and superior to those found in laboratories using expensive high-purity raw materials. We have established a new material composition (M alloy) that can be obtained from the above, a manufacturing method for the material that can be stably supplied, and a new heat treatment method for nanocrystallization.

We expect are confident that M alloy is going tcano be used in a wide range of products and lead to new innovations in soft magnetic materials.

Makino Co., Ltd. contributes to the realization of a carbon-neutral society through our patented technology “M alloy,” and aims to develop it into a wide range of applied products through intellectual property and technology licensing.

Akihiro Makino, Representative Director

Doctor of Engineering, Department of Metals and Materials Engineering, Graduate School of Engineering, Tohoku University.

After working in the research and development department of a private company and as a professor in the Akita Prefectural University's Department of Systems Science and Technology, he became a professor at the Institute for Materials Research of Tohoku University in 2005. In 2012, he served as director of the affiliated New Materials Joint Research and Development Center, and in the same year as the research representative of the Tohoku Materials Technology Leading Project (Ultra-low Loss Magnetic Core Materials Technology Area) supported by the Reconstruction Agency of Japan.

Dr. Makino is a professor emeritus at Tohoku University and has received numerous awards, including the Kahoku Cultural Award, Ichimura Academic Award, the 21st Century Invention Award, the Japan Institute of Metals and Materials Achievement Award, and the Minister of Education, Culture, Sports, Science, and Technology Award, and more.

Our Technology

Features of M alloy

The only innovative soft magnetic material that combines the highest magnetic flux density with the best soft magnetic properties.

Nanocrystalline soft magnetic alloy “M alloy” has high magnetic flux density, excellent soft magnetic properties, and low loss, which were considered difficult to achieve in the past.

Nanocrystalline soft magnetic alloy “M alloy” has high magnetic flux density, excellent soft magnetic properties, and low loss, which were considered difficult to achieve in the past.

Contact Us

LABO・CITY SENDAI

6-6-3 Minamiyoshinari, Aoba-ku, Sendai

Miyagi, 989-3204 JAPAN

TEL:+81-22-343-6877

E-mail:info akmakino.com

akmakino.com